K3 SEAT

Third model of a family of seats designed to elevate aesthetics, comfort and versatility to their maximum exponent, using environmentally friendly materials in their manufacture, which can be recycled separately.

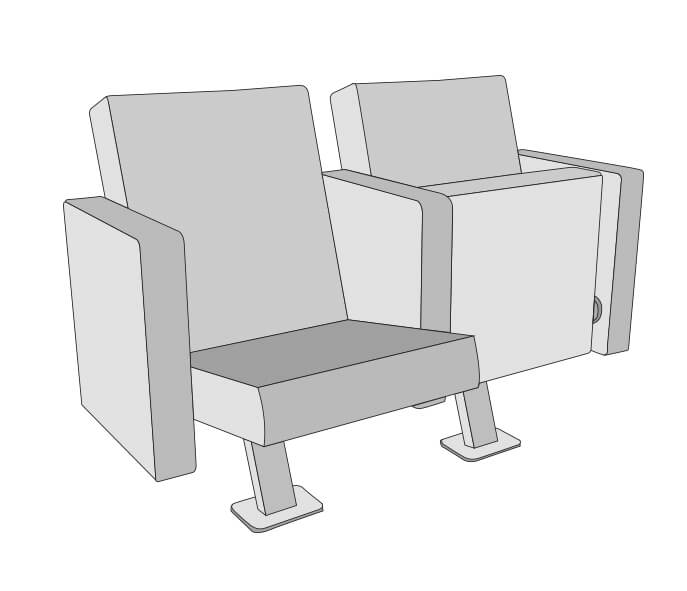

Versatility is defined not only by its variable dimensions, but also by the different shapes of the seat, backrest and side panel, which can be combined to achieve a better aesthetic adaptation to the space in each project.

Top quality finishes, in which the work of the master craftsmen involved in the manufacture of the wooden parts and upholstered elements can be appreciated, in processes that combine innovation in materials and the recovery of traditional methods.

Comfort as a result of the ergonomic design and manufacture of the seat and backrest assemblies, using variable density foam and elastic webbing.

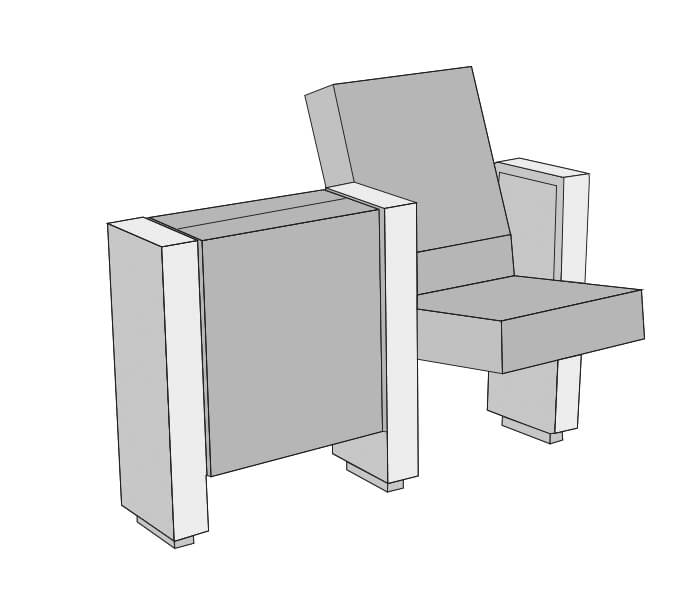

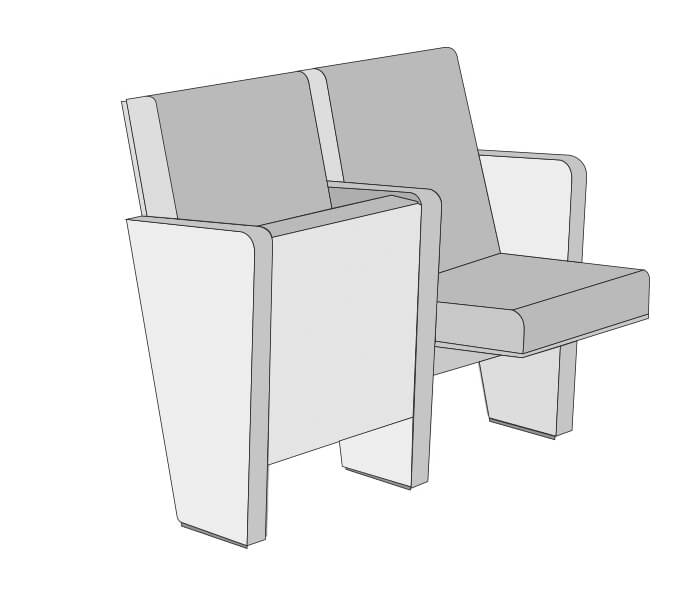

A rectangular-shaped side foot and rounded upper edges to soften its shape, in perfect harmony with the shape and alignment of the upper part of the backrest, are the defining features of this third model of the K family, which can be assembled with straight and continuous backrests with no separation between them, or discontinuously, with straight or curved backrests leaving a separation between them coinciding with the width of each of the side feet.

USES AND APPLICATIONS OF THE K3 SEAT

With a variable width between axes between 520 and 600 mm, it can be adapted to each of the spaces, and can be installed with different types of inclination, in distributions with straight rows or curved rows.

Variable aesthetics depending on the different finishes on each of the elements: upholstered seat and backrest combined with fairings made of plywood board finished in beech veneer, or fully upholstered seats and backrests; fully upholstered side panel or finished in beech veneer.

All these features make this model suitable for installation in all types of auditoriums, theaters and conference rooms.

K3 SUSTAINABLE SEAT

This product allows the use of upholstery woven with polyester yarns made from recycled PET bottles. In addition, to ensure the closing of the materials cycle, each and every element used in its manufacture can be recycled separately, thus reducing the ecological footprint.